This is Part 3 of this Rhino 3D tutorial.

>>> Click here to go back to Part 2.

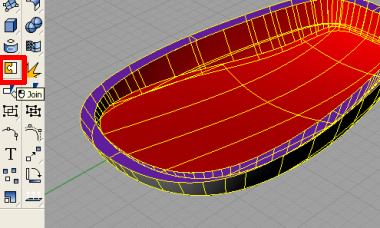

Use the Join command to join all the surfaces together. We will want to create a water-tight model that can be rapid-prototyped or exported to a Engineering CAD program such as Pro-engineer or Solidworks.

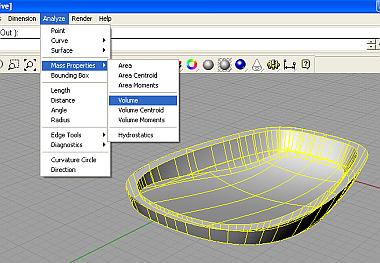

Next, go to Analyze >> Mass Properties >> Volume. If there is a volume, the model is fully enclosed with no gaps ( as per the tolerance setting within this environment). The model should now be water-tight.

Some points to take note

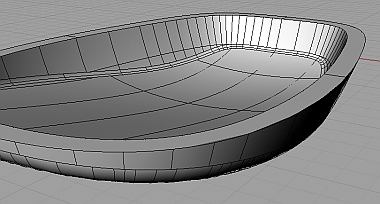

If the model needs to be filleted, it is better to do the filleting using the Mechanical CAD program that the engineering side of the design team has. This is especially true if the Mechanical CAD program is a parametric solid modeler such as Pro-Engineer, Alibre or Solidworks. This is because dedicated solid modellers are better than CAID modellers in handling fillets and radius-ed edges. Additionally, the parametric nature of these mechanical solid CAD programs allows for the flexibility to edit the radius where the need arises.

However, if you do need to fillet the 3D model within Rhino 3D, it should be done after the shelling steps have been executed.

That is the end of this Rhino 3D tutorial.

Thanks for reading 🙂